Canned products are generally packaged with automatic c […]

Canned products are generally packaged with automatic can sealing machines. We need to process the cans before packaging.

Before canning, first put sterilized glass (1354,-18.00,-1.31%), we take canned pears as an example, put 290 grams of fruit pieces in the pear cans (depending on different canned products) , add 220 grams of sugar water to heat the exhaust.

After canning, it is sent to the exhaust box for heating and exhausting, and the temperature of the center of the can is above 80 °C.

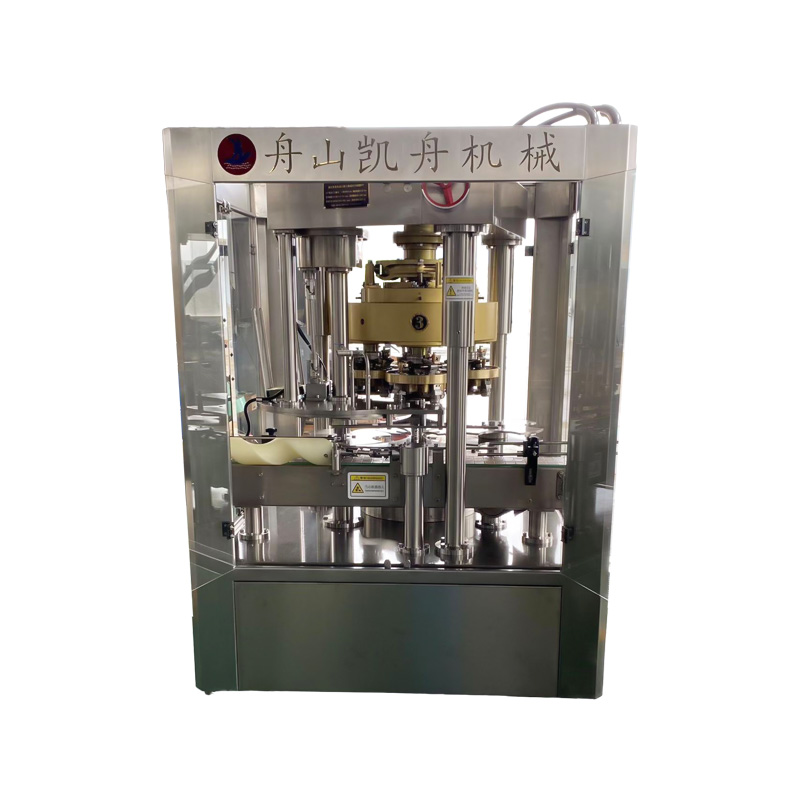

Canned. Put the lid on the can, and seal the can on the automatic can sealing machine without air leakage.

Sterilization and cooling. Boil the can in boiling water for 15 to 20 minutes, then cool to 38°C in stages.

Wipe cans, put in storage. Wipe dry and store in a room temperature warehouse for one week.

The quality requirements of the automatic sealing machine for pears The pulp is white or yellow, and the color is relatively consistent. Sugar water is more transparent. A small amount of pulp debris that does not cause cloudiness is allowed. It has the flavor that this variety of canned pears should have, sweet and sour taste, no peculiar smell. The tissue of pear slices is moderately soft and hard, and there is no rough stone cell feeling when eating. The block is complete. The fruit pieces in the same jar are the same size. Without automatic seamer damage and pest spots. The pulp should not be less than 55% of the total net weight. The concentration of sugar water is not less than 14%-18% (refractometer when opening the can). Other canned products are packaged in the same way as pears, but with different ingredients.

Matters needing attention when using the automatic sealing machine:

For varieties with acidity lower than 0.1%, 0.15%-0.2% citric acid should be added to the sugar water.

The production process must be rapid, especially in the handling of fruit, canning and sterilization.

When pre-cooking, it is necessary to have a lot of water, enough steam, and an appropriate amount, so that it can penetrate and not rot.

Do not use pears with low maturity or frozen storage. When producing snow pears in Tangshui in winter, soak them in boiled pear water at about 30°C for 30 minutes to prevent the pears from discoloring during pre-cooking.